APC LensPro for Omtech Polar / Gweike Cloud Magnetic Lens Upgrade

APC LensPro for Omtech Polar / Gweike Cloud Magnetic Lens Upgrade - is backordered and will ship as soon as it is back in stock.

Care information

Care information

High care information about CO2 laser lenses, fiber laser protective windows, and

fiber laser lenses is essential to ensure the optimal performance and longevity

of these critical components in laser systems. Here are some key points to consider:

CO2 Laser Lenses:

Cleaning:

Regularly clean CO2 laser lenses to remove dust, debris, and residue. Use a

soft, lint-free cloth or lens cleaning tissue. Avoid using abrasive materials

that may scratch the lens.

Handling:

Always handle CO2 lenses with clean hands or lint-free gloves to avoid transferring oils or contaminants onto the lens surface.

Storage:

Store lenses in a clean, dry, and dust-free environment to prevent damage and

maintain their integrity.

Alignment:

Properly align CO2 lenses within the laser system to ensure efficient laser

beam delivery and focus.

Inspection:

Regularly inspect lenses for signs of damage, scratches, or deterioration.

Replace any damaged or worn lenses promptly.

Fiber

Laser Protective Windows:

Cleaning:

Clean fiber laser protective windows with care to avoid scratches. Use a gentle

cleaning solution and a soft, lint-free cloth.

Protection:

Keep protective windows in place when the laser system is not in use to prevent

contamination and damage.

Replacement:

If protective windows become damaged, replace them immediately to maintain

laser system safety and performance.

Fiber Laser Lenses:

Cleaning:

Clean fiber laser lenses carefully to prevent damage. Use a lens cleaning

solution and a soft, lint-free cloth or lens tissue.

Handling:

Handle fiber laser lenses with care to avoid fingerprints, oils, or scratches

on the lens surface.

Alignment:

Properly align fiber laser lenses to ensure accurate laser beam focusing and

efficient performance.

Inspection:

Regularly inspect fiber laser lenses for signs of wear, damage, or contamination. Replace any compromised lenses promptly.

Environmental Considerations: Be mindful of environmental factors such as temperature and

humidity, as extreme conditions may affect lens performance.

Overall,

maintaining high care and attention to detail when handling, cleaning, and

storing CO2 laser lenses, fiber laser protective windows, and fiber laser

lenses will enhance their longevity and contribute to the smooth and reliable

operation of your laser systems. Always follow the manufacturer's guidelines

and best practices for each specific component to ensure optimal results.

Delivery and Shipping

Delivery and Shipping

FOR ITEMS IN STOCK:

Orders placed before 2:00 pm EST/EDT on a business day

(Monday - Friday) will ship the same day.

Orders placed after 2:00 pm EST/EDT may not be be shipped

until the next business day.

Our business hours are Monday to Friday, 9 am-4:30 pm.

Orders placed after business hours will not be processed

until the next business day.

Orders placed during the weekend (Saturday - Sunday) or

holiday will be shipped on the next business day.

All packages are shipped FOB ORIGIN – These shipping terms

are characteristic of a “SHIPMENT CONTRACT” and the seller bears the expense

and risk of putting the goods in the possession of the carrier. Title transfers to the buyer at the point when the goods leave the shipper’s loading dock but reverts back to the seller if the buyer follows the correct procedures of notifying the seller of “breach” by “rightfully revoking cceptance.” Even if “breach” has occurred, the buyer remains responsible for filing “carrier loss

claims.”

*The magnetic tube is compatible with the stock air assist nozzle. It does not need the American Photonics air assist adaptor.

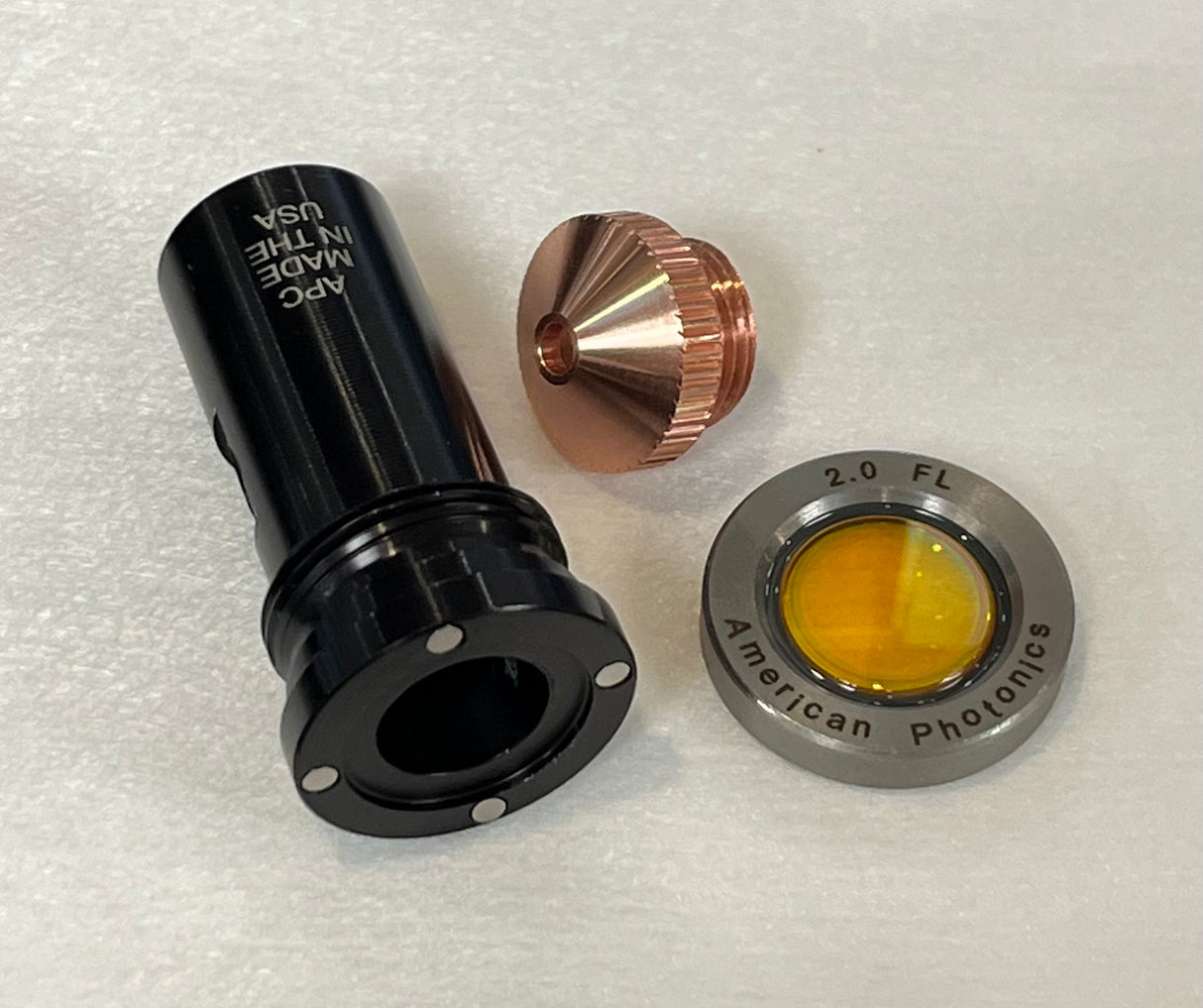

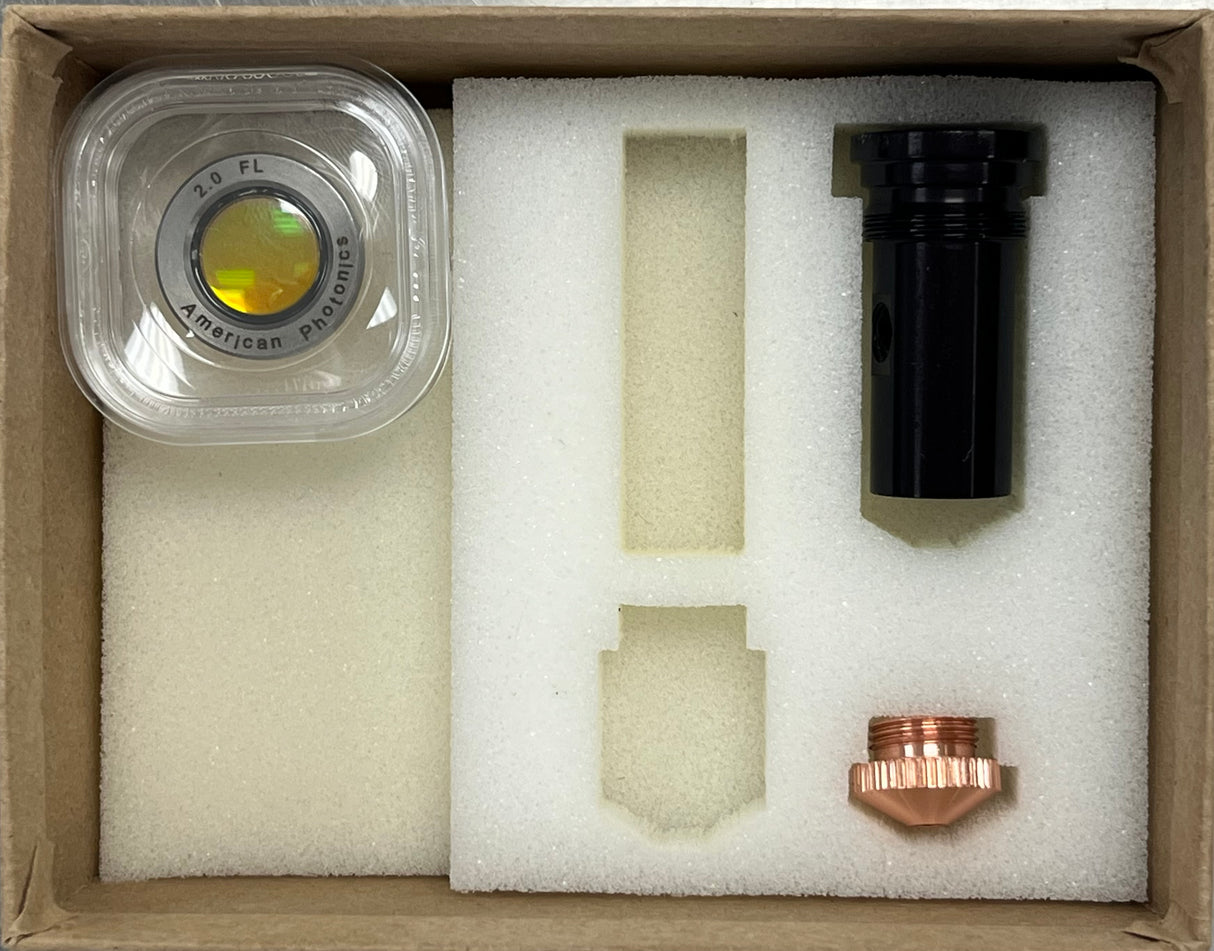

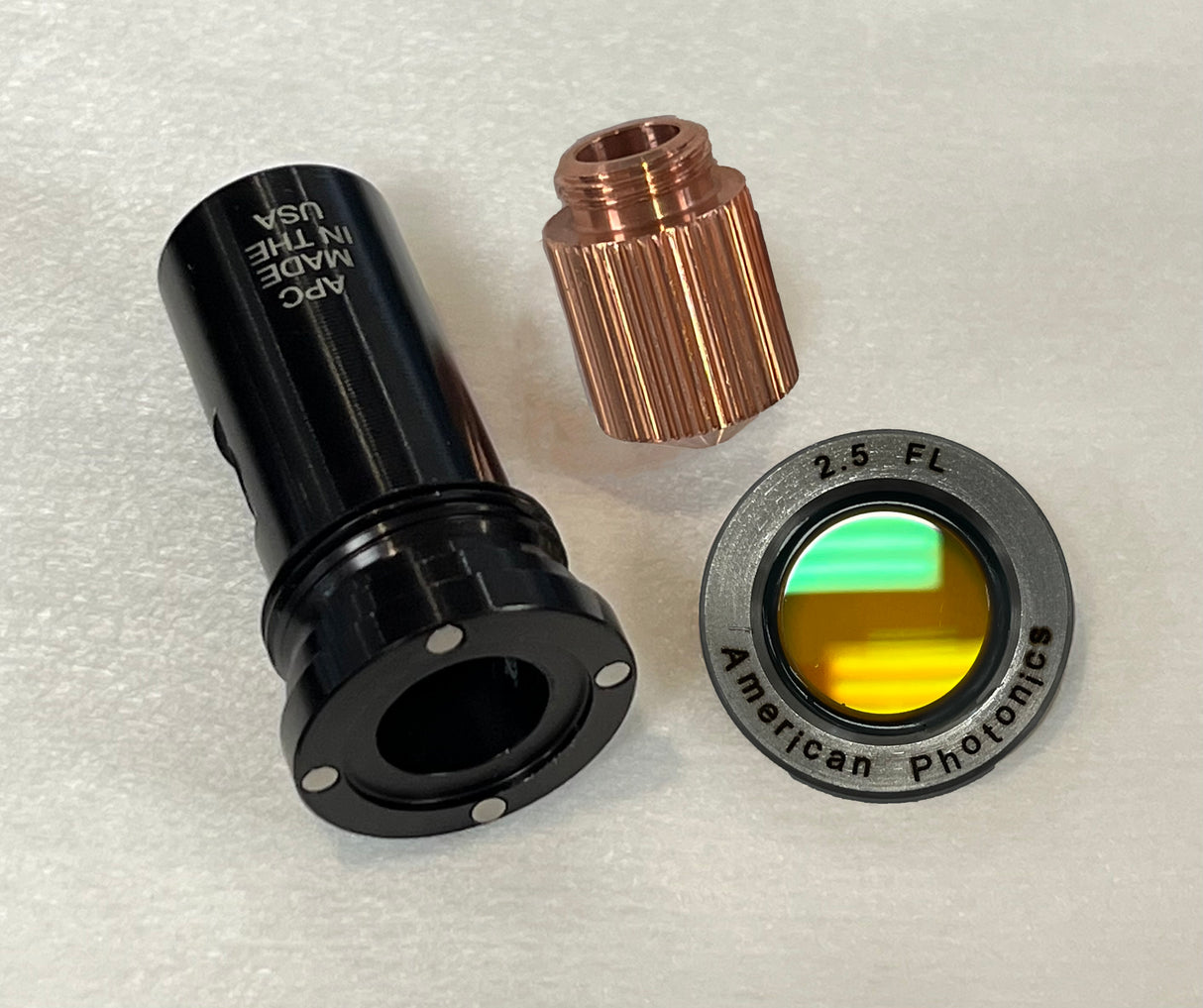

Get ready for precision and clarity like never before with the APC LensPro for Omtech® Polar and Gweike® Cloud. This game-changing lens upgrade is designed to enhance your desktop laser machine's performance and make daily lens cleaning a snap.

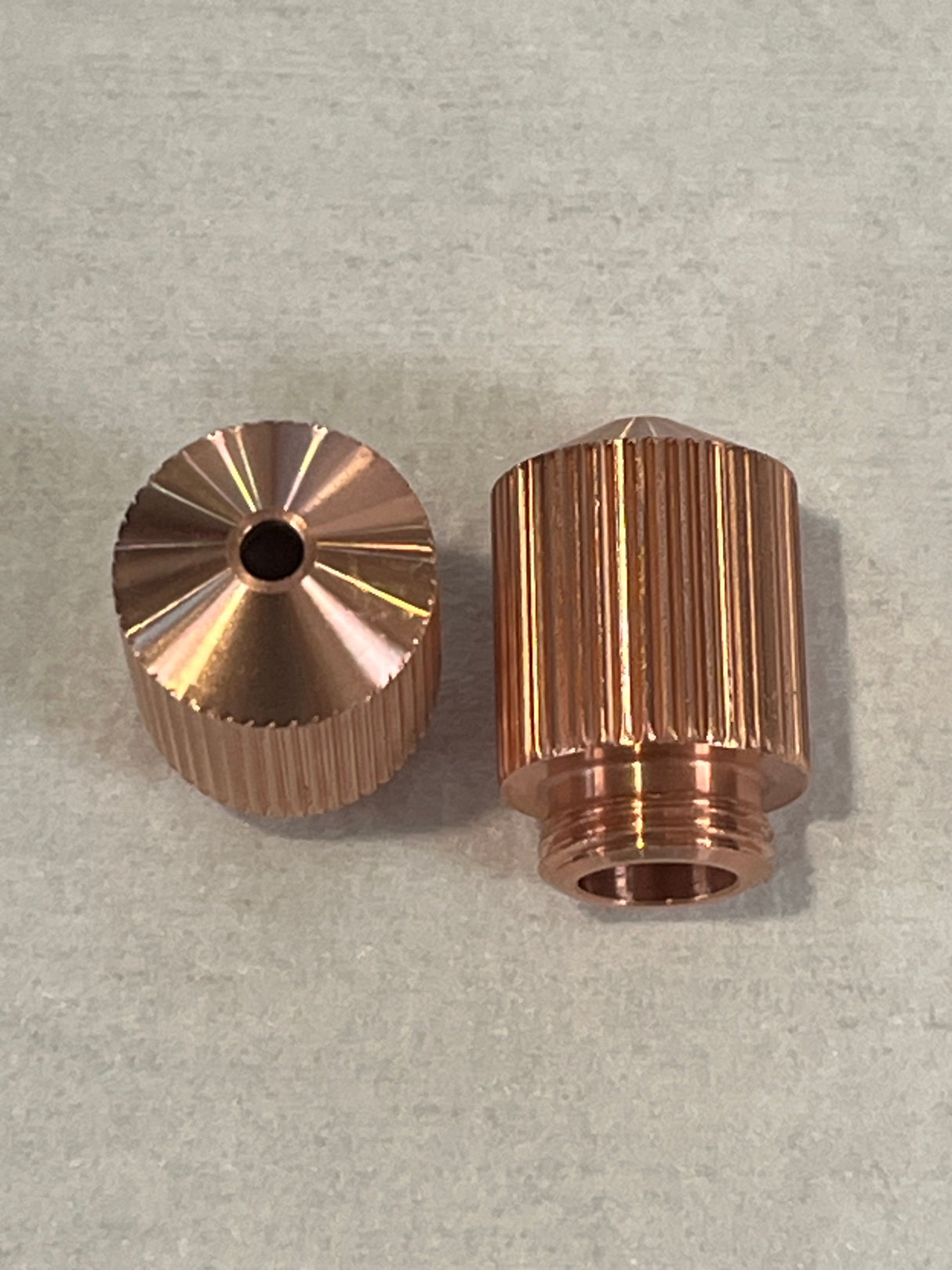

Our 2" copper nozzle can replace your original plastic nozzle.

Buy the 3 piece bundle and save 10% !!

We Appreciate Your Valuable Feedback !!!

Introducing the APC LensPro for Omtech® Polar: Elevate Your Laser Lens Care!

Get ready for precision and clarity like never before with our latest offering: the APC LensPro for Omtech® Polar. We're thrilled to introduce this game-changing lens care solution to enhance your laser machine's performance.

Download the height gauge. click the links below

Height Gauge cut files for APC LensPro

Focal length testing for the APC LensPro

Key Features:

1. Dual-Component Design: The APC LensPro is a two-part solution comprising a precision-mounted lens, and a magnetic tube for effortless removal and cleaning. This dynamic duo ensures a seamless and efficient lens maintenance process, making it easier than ever to keep your lens crystal clear.

2. Omtech® Polar & Gweike® Cloud Compatibility: Tailored exclusively for these laser machines, the APC LensPro is the perfect companion for your equipment. It's engineered to meet the unique requirements of your laser, guaranteeing a perfect fit and exceptional performance.

3. Prolonged Lens Life: Regular cleaning is essential to extend the life of your laser lens. The APC LensPro simplifies this task, helping you maintain a clean lens surface for longer-lasting, high-quality laser work.

4. Enhanced Precision: Clean lenses are vital for precise laser cutting and engraving. With the APC LensPro, you can trust that your Omtech® Polar machine will consistently deliver outstanding results.

5. User-Friendly Design: Say goodbye to cumbersome lens maintenance. The magnetic tube allows for quick and hassle-free lens removal, and the sturdy construction ensures protection against accidental drops or damage during cleaning.

Don't miss this opportunity to upgrade your lens care routine and elevate your laser machine's performance. Invest in the longevity and precision of your Omtech® Polar laser machine with the APC LensPro. It's your dedicated solution for keeping your lens in top-notch condition, ensuring that your laser projects maintain the highest standards of clarity and accuracy.

APC #LensPro #AmericanPhotonics

Here's a detailed description of why you might choose a 2.0", 2.5", or 4.0" Focal Length (FL) lens, along with examples of materials and applications for each:

2.0" Focal Length (FL) Lens: Precision in Detail

The 2.0" FL lens is akin to a magnifying glass for your laser, focusing the beam to a tiny pinpoint spot. This precision makes it ideal for intricate and detailed engraving tasks where accuracy and fine details matter most.

Applications:

- Jewelry Engraving: Create intricate designs on precious metals with unparalleled precision.

- Small Text Marking: Perfect for marking small text and intricate patterns on various materials.

- High-Resolution Engraving: Achieve high-resolution engraving on materials like wood, acrylic, and leather.

2.5" Focal Length (FL) Lens: Versatility Meets Depth

The 2.5" FL lens strikes a balance between depth and precision, making it a versatile choice for a wide range of engraving and cutting tasks. It offers increased focal length compared to the 2.0" lens, allowing you to work on thicker materials without sacrificing too much precision.

Applications:

- Glass Engraving: Ideal for engraving on glass surfaces while maintaining excellent precision.

- Rubber Cutting: Provides a versatile solution for cutting rubber materials with precision.

- Fabric Marking: Perfect for fabric engraving and marking applications.

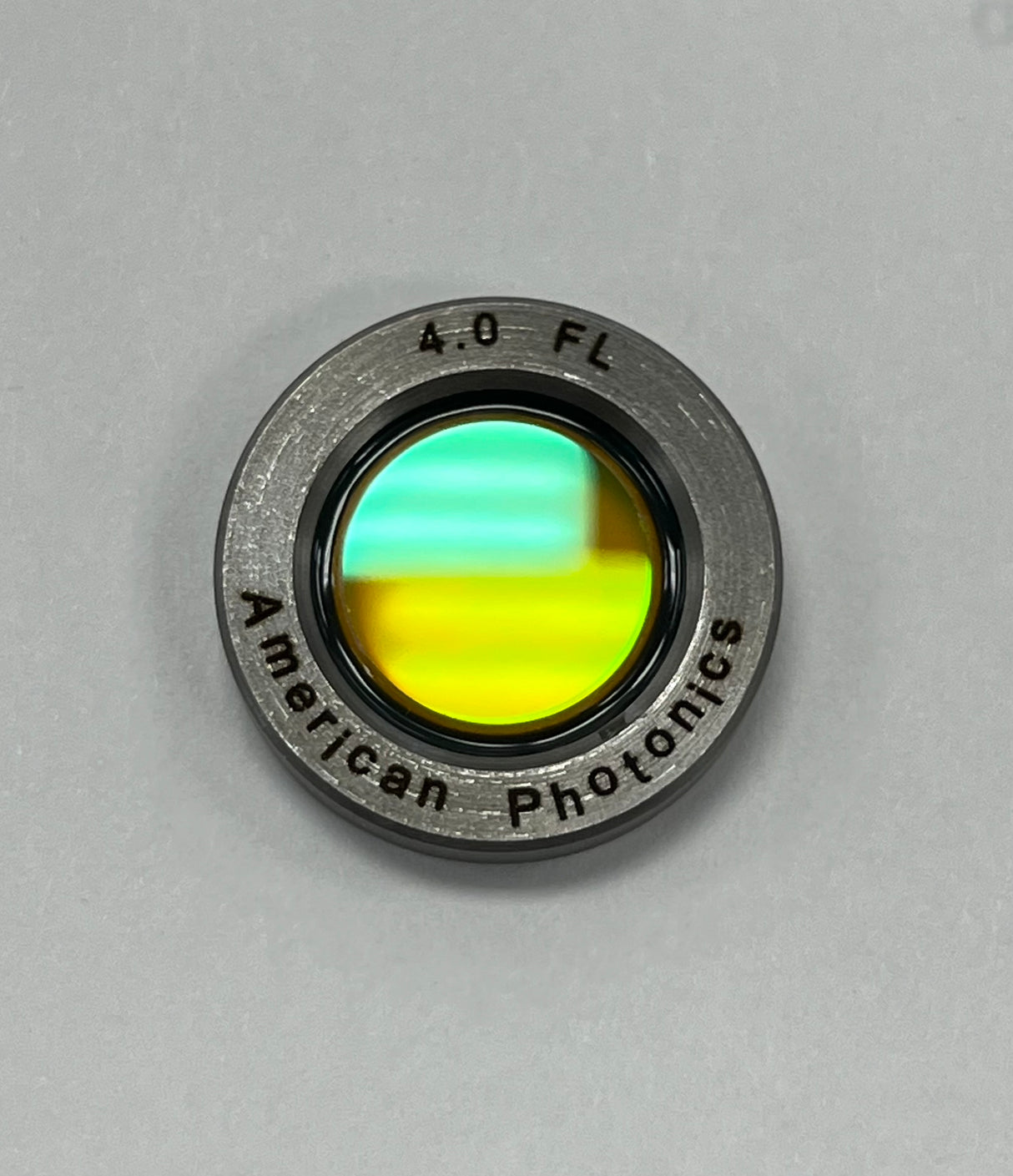

4.0" Focal Length (FL) Lens: Power for Thicker Materials

When you need to engrave or cut through thicker materials or require a more extended focal point, the 4.0" FL lens is the answer. It offers a more extended focal length, making it suitable for tasks that demand extra depth.

Applications:

- Deep Engraving: Ideal for deep engraving on materials like cardboard and acrylic.

- Cutting Thicker Materials: Easily cut through thicker materials such as cardboard and foam.

- Cylindrical Objects: Use it for engraving and marking on cylindrical objects.

Choosing the right FL lens depends on your project's specific requirements. Whether you're crafting intricate jewelry, creating signage, or customizing promotional items, understanding these FL options and their applications will help you achieve the desired results. Remember that while these guidelines are helpful, experience and experimentation will also play a role in refining your laser engraving and cutting techniques. Upgrade your lens, and elevate your laser work to new heights of precision and excellence.

Need help understanding your laser lens specs like Focal Length (FL), Diameter (Dia), or Edge Thickness (ET)? Our blog has you covered! Check it out here: Choosing the Right Co2 Lens Blog for quick and easy insights.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

KeyFeatures of Our Products: